3D PRINTING

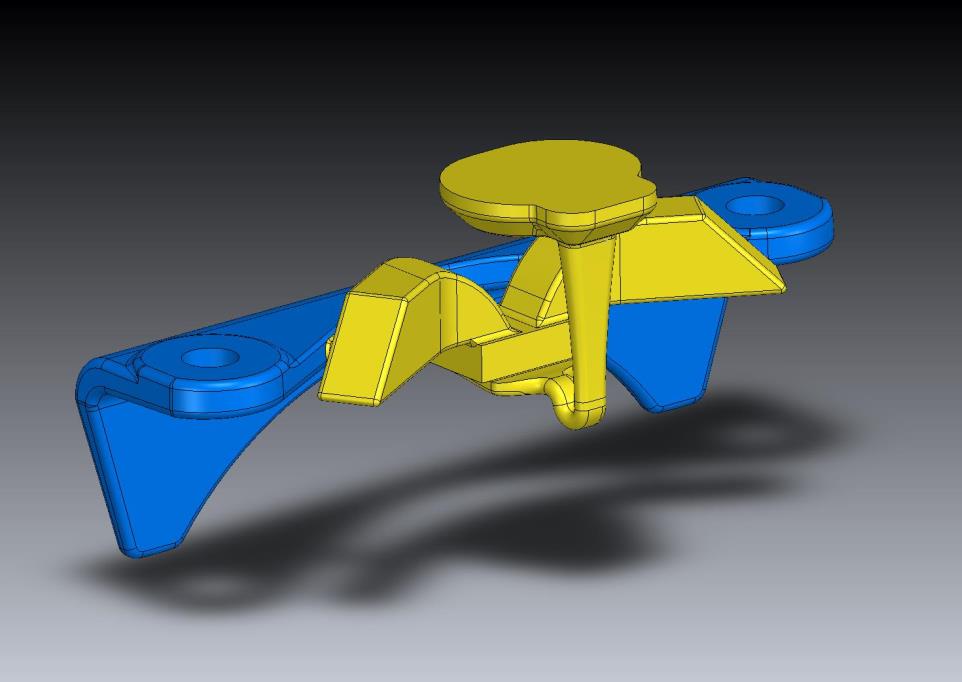

3D Printing ( additive manufacturing) is a process of producing 3-Dimensional objects from a digital design. There are multiple 3D printing materials and technologies but all use the same concept; a digitally designed model is processed into a solid 3D product by adding material layer after layer.

HOW 3D PRINTING WORKS

The 3D digital design file is the blueprint of the physical 3D object. The design file is thinly sliced into layers that are then sent to the printer. Thereafter the printing process starts, but varies depending on the type of technology used from desktop printers which melt (plastic) material & lay the melted material down on a print platform to industrial machines which melt metallic powders at very high temperatures using laser. Time taken to complete a printing process depends on the object size.

This technology can be used in aircraft industry, automotive industry, packaging industry and also the health sector.

BENEFITS 3D PRINTING

AFFORDABLE

Traditional ways of image prototyping and production are expensive. 3D printers have the most affordable production options by creating and manufacturing parts and tools that are cheap compared to the traditional machines. e.g. in the medical field, 3D printing tools such as forceps, clamps, scalpel handles and hemostats are cheaper to buy when compared to stainless steel. Furthermore,the cost of 3d printing prosthetics are cheaper than the traditional ones.

Traditional ways of image prototyping and production are expensive. 3D printers have the most affordable production options by creating and manufacturing parts and tools that are cheap compared to the traditional machines. e.g. in the medical field, 3D printing tools such as forceps, clamps, scalpel handles and hemostats are cheaper to buy when compared to stainless steel. Furthermore,the cost of 3d printing prosthetics are cheaper than the traditional ones.

EASY TO CUSTOMIZE

Most industries manufacture their products by mass production i.e. all the produced products use the same type of molding, and all the end products have similar design and shape, with no uniqueness. With 3D printing, one can personalize anything by simply tweaking any part of the prototype to cater for their specific needs. For example, a customized 3D printing can be used in dental and medical field.

MATERIAL DIVERSITY

In the case of mass production, mixing of raw material is not always ideal as it can be costly. The chemical and physical properties are also difficult to mix when using the traditional methods. 3D printing, however, offers continuous progress in this area. Apart from using plastics, 3D printing has multiple material compatibility from glass, gold, silver, ceramics, biomaterials, paper and food. With all these materials at hand, one can accomplish anything they have in mind with 3D Printing.

FAST PRODUCTION

Traditional machine production requires machines and human labor for production which are all expensive. This can take time due to expenses and arrangements involved, leading to a lot of time wastage. 3D Printing takes only hours. After the design, after that file are to readable by the printer and thereafter printing is done. There is no waiting queues and the marketing of products is fast and easy leading to quick turnarounds.

Traditional machine production requires machines and human labor for production which are all expensive. This can take time due to expenses and arrangements involved, leading to a lot of time wastage. 3D Printing takes only hours. After the design, after that file are to readable by the printer and thereafter printing is done. There is no waiting queues and the marketing of products is fast and easy leading to quick turnarounds.